A vital component of the healthcare supply chain, pharmaceutical distribution makes sure that medications are delivered to patients promptly and securely. Nonetheless, this sector has particular difficulties that may result in operational inefficiencies and public health hazards. Retaining profitability, compliance, and trust requires acknowledging and correcting these errors.

1. Inadequate Demand Forecasting

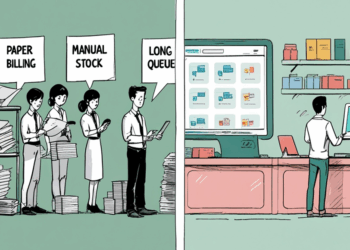

Demand forecasting plays a crucial role in maintaining an efficient pharmaceutical supply chain. A lot of distribution centers employ antiquated techniques or incomplete data, which can lead to serious errors in computations.

For example, seasonal trends, sudden health crises, and regional preferences often go unnoticed without robust forecasting models.

Overstocking, a common issue, not only ties up working capital but also leads to losses when medicines expire. For items with a short shelf life, such biologics or medications that are sensitive to temperature, this is especially troublesome. On the other hand, understocking disrupts supplies, making it impossible for pharmacies and medical institutions to satisfy patient demands.

Advanced Forecasting Tools

Modern forecasting tools incorporate machine learning and AI to analyze large datasets, including historical sales records, epidemiological trends, and external factors like weather or economic conditions. For instance, during flu season, demand for antiviral drugs and vaccines typically surges. Distribution houses can better prepare for these increases thanks to AI-based solutions that can forecast them.

Collaboration with Pharmacies and Hospitals

Close coordination with healthcare providers ensures a clearer understanding of real-time demand. Sharing data with pharmacies and hospitals allows distribution houses to adjust supply levels dynamically. The danger of both overstocking and understocking is reduced by this cooperative strategy.

2. Poor Cold Chain Management

Maintaining the effectiveness of medications that are sensitive to temperature, such as vaccinations, insulin, and biologics, requires careful cold chain management. Many distribution centers struggle to maintain the necessary conditions, despite their significance. Problems including power outages, poor storage facilities, and incorrect handling during transportation can cause items to sustain irreparable harm.

Real-Time Monitoring Solutions

Cold chain management has been transformed by sophisticated IoT-enabled sensors and GPS tracking devices. These gadgets guarantee that items stay within specified parameters by continuously monitoring temperature, humidity, and location. In the event of a deviation, the system notifies users so that prompt remedial action may be taken.

For example, a logistics company transporting vaccines can use IoT sensors to detect temperature changes in real time. If a refrigeration unit fails, an alert notifies the driver and the logistics team, allowing them to reroute the shipment to the nearest backup storage facility.

Standardized Packaging and Protocols

High-quality insulated packaging and phase-change materials are essential for maintaining temperature stability. Training staff on proper loading and unloading practices also minimizes exposure to adverse conditions. Error risk is decreased by using a standardized technique, which guarantees consistency across the supply chain.

3. Lack of Regulatory Compliance

Regulatory compliance is a cornerstone of pharmaceutical distribution. In addition to putting product quality at risk, breaking rules like GDP exposes companies to harsh fines. Inadequate paperwork, irregular procedures, and an inability to stay abreast of regulatory developments are problems that many distribution firms face.

Robust Documentation Systems

Accurate and comprehensive records are essential for demonstrating compliance. Digital solutions that centralize and make easily accessible records, such cloud-based documentation systems, streamline the process. In order to guarantee compliance with changing rules, these systems also allow for automated upgrades.

Internal Compliance Audits

Regular internal audits help identify gaps in compliance and address them proactively. Quarterly inspections of storage facilities, for instance, guarantee that they adhere to hygienic and temperature control regulations. Proof of compliance for external inspections can be obtained by documenting these audits.

Training and Awareness

It’s crucial to make sure every employee is aware of how important regulatory compliance is. Workshops and certification programs focusing on GDP principles equip staff with the knowledge to handle pharmaceutical products correctly and maintain documentation standards.

4. Insufficient Staff Training

The procedure of distributing pharmaceuticals has intricate duties that call for qualified staff. Mistakes like improper paperwork, improper handling of delicate materials, or improper storage are frequently the result of inadequate training.

For example, staff unaware of the importance of cold chain integrity may inadvertently expose products to harmful conditions, resulting in loss of inventory and regulatory violations.

Solution:

Regular training programs tailored to specific roles are essential. These courses ought to address GDP regulations, appropriate handling practices, and the application of technology in distribution. Employees are kept up to speed on best practices through the provision of certificates and refresher training.

5. Ineffective Supply Chain Visibility

Limited visibility into the supply chain can lead to inefficiencies and increased risks. Distribution houses that lack end-to-end tracking capabilities often struggle with delayed deliveries, inventory mismatches, and untraceable product recalls.

For instance, during a recall, identifying affected batches quickly is critical. This procedure becomes laborious and prone to mistakes in the absence of sufficient visibility, endangering the patients.

Solution:

Adopting digital tools that provide real-time tracking and analytics can enhance supply chain visibility. Blockchain technology provides a visible, unchangeable record of transactions, enhancing accountability and traceability. In order to take preventative action against interruptions, these technologies also assist in identifying bottlenecks.

6. Overreliance on Single Suppliers

Depending heavily on a single supplier for critical components or raw materials poses a significant risk. Natural catastrophes, geopolitical conflicts, or supplier bankruptcies are examples of disruptions that might stop operations and affect the supply of medications.

For example, the global shortage of active pharmaceutical ingredients (APIs) during the COVID-19 pandemic highlighted the risks of over dependence on specific regions for sourcing.

Solution:

Diversifying the supplier base reduces the risk of supply chain disruptions. Creating backup plans and cultivating connections with several suppliers guarantees continuation even under unfavorable circumstances. Supply chain resilience is further increased by doing risk assessments and routinely assessing supplier performance.

7. Failure to Address Last-Mile Challenges

Last-mile delivery is often the most complex and costly segment of the pharmaceutical supply chain. Delays, incorrect addresses, and mishandling during this stage can compromise product integrity and patient health.

Optimized Delivery Routes

Route optimization software uses algorithms to identify the fastest and most efficient paths for delivery. These tools factor in variables like traffic patterns, weather, and delivery priorities, ensuring timely arrivals. For example, a pharmacy requiring an urgent supply of antibiotics can be prioritized in the delivery schedule.

Specialized Delivery Vehicles

Temperature-controlled vehicles equipped with real-time tracking systems ensure that products remain safe during transit. These vehicles are particularly important for transporting biologics or chemotherapy drugs, where even minor temperature deviations can result in product failure.

Collaboration with Local Partners

Partnering with local logistics providers helps overcome regional challenges, such as difficult terrain or unfamiliar routes. Local expertise ensures smoother operations and reduces delivery delays.

8. Ignoring Sustainability Practices

Sustainability is becoming a key consideration in pharmaceutical distribution. Ignoring environmentally friendly practices, such as waste reduction and energy-efficient operations, not only harms the planet but also risks alienating customers and partners.

For example, excessive use of non-recyclable packaging materials contributes to environmental degradation and increases operational costs.

Solution:

Adopting sustainable practices, such as using biodegradable packaging and optimizing transportation routes to reduce fuel consumption, benefits both the environment and business. Highlighting these initiatives in marketing communications can also enhance the brand’s reputation.

9. Inefficient Communication Channels

Clear and timely communication is crucial for coordinating complex supply chain operations. Miscommunication between teams or with suppliers often leads to errors, delays, and increased costs.

For instance, a delay in communicating order changes to a supplier can result in overproduction or missed deadlines.

Solution:

Implementing centralized communication platforms streamlines interactions between stakeholders. Tools that integrate messaging, task management, and document sharing improve coordination and reduce misunderstandings. Regular meetings and updates further align teams on priorities and challenges.

10. Neglecting Risk Management

Risks including cyberattacks, natural catastrophes, and regulatory changes are all present in the high-stakes world of pharmaceutical distribution companies. Financial losses and significant disruptions may result from a failure to prepare for these risks.

Comprehensive Risk Assessment

A thorough risk assessment identifies vulnerabilities in the supply chain. Assessing the dependability of logistics partners and suppliers, for example, might reveal possible vulnerabilities. Distribution centers can create backup plans to reduce risks by using this information.

Investing in Cybersecurity

As the industry becomes more reliant on digital tools, cybersecurity is a growing concern. Cyberattacks targeting sensitive data or operational systems can cripple distribution networks. The danger of breaches is reduced by putting in place robust firewalls, encryption procedures, and staff training initiatives.

Disaster Recovery Protocols

Natural disasters, such as floods or earthquakes, can disrupt supply chain operations. Preparing for such occurrences entails arranging alternate logistical routes in advance and setting up backup warehouses in safer areas. Frequent simulations and exercises guarantee that staff members are equipped to handle crises with effectiveness.

Conclusion

Pharmaceutical distribution centers are essential to the healthcare industry, but they deal with many issues that may affect their dependability and efficiency. These companies may improve their operations and guarantee the safe delivery of medications by addressing typical errors such as inadequate demand forecasting, poor cold chain management, and inadequate personnel training.

Distribution companies may develop resilience and maintain their competitiveness in a sector that is changing quickly by using cutting-edge technology, diversifying their suppliers, and demonstrating a dedication to sustainability. Businesses and the patients they serve will eventually gain from a focus on proactive problem-solving and continual development.

Great insights on the challenges in pharma distribution! InadequatePharma Distribution Comment Creation demand forecasting is definitely a major issue, especially when it leads to overstocking and expired medications. One approach that could help is integrating real-time data analytics to track seasonal trends and sudden demand shifts—have you seen any success stories of companies implementing this effectively?